Heavy-equipment manufacturer Normet Oy is carrying out a vision for building a customer-serving future on strategies based in large part on state-of-the-art manufacturing and digital commerce.

In underground mines and tunneling projects, Normet’s new SmartDrive battery-electric-powered and massive mining and construction equipment comes with benefits similar to those of modern electric cars: “one-pedal” driving and relatively sleek designs emanating from the lack of traditional gearboxes and driveshafts.

Normet’s drive into electric vehicles coincides with its foray into digitalization — two developments the Espoo, Finland-based company highlights in its 2022 annual report as among the critical industry trends supporting the manufacturer’s long-term growth.

“We continue to expand our core process areas, with advances in electrification, digitalization, automation, and technology leadership,” president and CEO Ed Santamaria says in the annual report.

Normet has also positioned itself for growth amid other significant trends impacting its industry: mines moving further underground, an increase in remote locations, and customers expecting more options and ease in dealing with the manufacturer and ordering parts, supplies and services to keep their costly equipment running in top shape.

Pekka Jaarinen, director of digital services, Normet Oy

Digital commerce is critical to addressing these trends, says Pekka Jaarinen, director of digital services.

“We are able to react faster to customer requests, and the customer has better transparency” into the availability of products and services and their order status, he says. “But it has improved our internal efficiency as well.”

Normet’s equipment ranges from multi-ton mobile mining equipment to cement-spraying trucks costing in the tens of thousands of dollars or more; the manufacturer’s new online store provides a quicker and more helpful way to order parts, supplies and services.

In addition, the digital channel extends Normet’s market reach, expands revenue opportunities, and provides a more helpful and accessible buying experience for customers. Moreover, its new ecommerce site runs on technology designed to be highly customizable — an advantage Normet is already using to develop new ways to interact with and serve customers.

Customizing a site based on customer feedback

The manufacturer’s first ecommerce site — launched as a pilot project last year in Australia and extended this year to the United States and Canada — is processing customer orders on a commercetools digital technology platform designed for customization, resulting in increased sales, including upselling and cross-selling transactions, and a 75% reduction in calls to customer service, Jaarinen says.

Normet says the digital Normet Store is helping to both attract and retain customers. The company plans to introduce new features as it learns more about how its customers want to use its new ecommerce channel.

“Our approach is to listen to customer feedback,” Jaarinen says. “We want to take a step-by-step approach to develop features that help make commerce easier for us — but especially for our customers.”

Companies that invest in Normet’s equipment typically lay out extensive capital for their mining or tunneling projects; they rely on steady connections with Normet and their maintenance contractors to order supplies, replacement parts and services to keep their equipment running smoothly.

Normet SmartDrive battery-electric mining equipment at work underground.

“These companies are investing hundreds of millions of dollars for getting the infrastructure in place before they get any money out of the ground,” Jaarinen says. “The environment they operate in is quite harsh, the conditions quite extreme, so they want to make sure that whatever equipment or machines they buy from Normet are maintained and running all the time.”

A better way to order from remote job sites

Normet’s customers, however, have relied for years on phone and email communications between their personnel, contractors and Normet to order what they need from the 65,000 products in the manufacturer’s catalog. But phone and email ordering can be tedious and time-consuming, requiring multiple back-and-forth comments among the several parties to ensure they’re bundling the correct mix of items and services for multi-ton mining and tunneling equipment.

Moreover, with many job sites in remote locations far from Normet service personnel, customers and their maintenance contractors rely even more on electronic communications that are faster and more accurate than traditional ordering methods.

“The customer locations are extremely remote,” Jaarinen says, adding, “So using the digital channels, we can get actually close to the customer and be more personalized. We know what machines they are running; we know what parts should be there. If a customer is trying to buy a part A, we can also say, hey, if you buy this, it makes sense to also replace part B.”

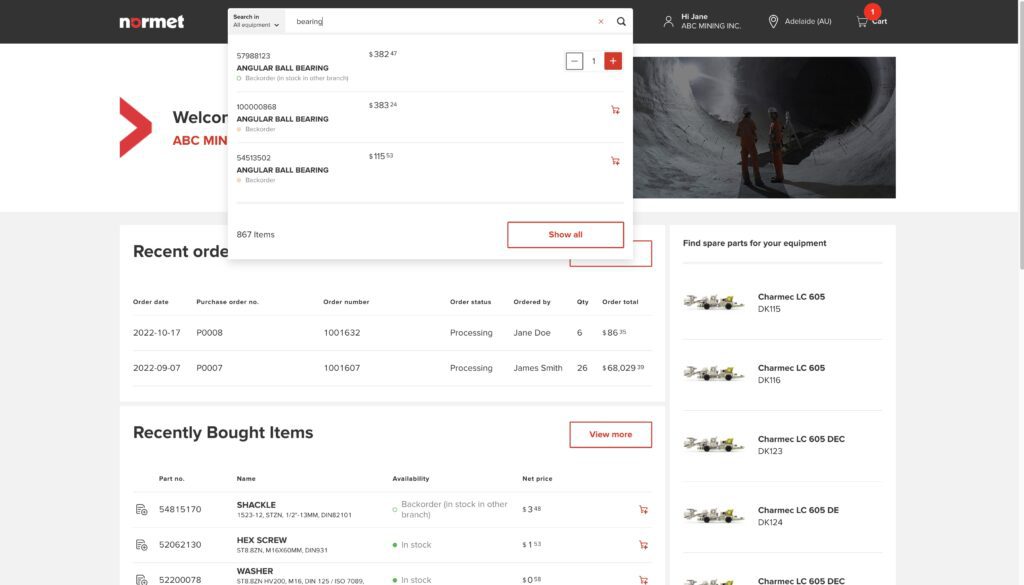

A sample mining equipment product landing page on the online Normet Store.

Because such online interactions are automatic, they avoid situations where human error or forgetfulness fails to recommend the correct products customers need to keep their equipment running, Jaarinen says.

Normet doesn’t break out ecommerce sales transaction figures. However, its ecommerce site’s third-quarter 2022 launch preceded a full-year 22% increase in total revenue to 439.24 million euros (US$480.17 million) for the year ended Dec. 31. Profit for the full year rose 31% to 36.69 million euros (US$40.11 million).

A flexible ecommerce platform for what lies ahead

Normet’s ecommerce opportunities are just beginning, Jaarinen says.

To give Normet the flexibility it needs to keep developing its ecommerce channel, Normet decided to deploy ecommerce technology it figured it could modify as needed to meet future challenges and opportunities.

Its Normet Store ecommerce site, store.normet.com, requires users to log in and runs on the commercetools Composable Commerce for B2B as its primary ecommerce infrastructure.

The MACH-based platform encompasses microservices, an API-first development platform, scalable cloud-based applications, and headless commerce technology. The headless commerce design separates the customer-facing front-end interface from the ecommerce engine and the enterprise resource planning system. The current version of Composable Commerce for B2B was refreshed last fall with “next-gen flexibility” with an API portfolio designed for building a customizable commerce infrastructure, says commercetools chief product officer Mike Sharp.

IT services firm Columbus Global led the commercetools implementation, which took about 4.5 months, Jaarinen says. Developed with responsive web design, the site is accessible via mobile devices but doesn’t have a related mobile app.

Because this was Normet’s first ecommerce site, he adds, the overall deployment of the new ecommerce platform was easier than it would have been if the manufacturer had to replace a pre-existing ecommerce technology.

Smoothing out the purchasing process

Jaarinen says the MACH infrastructure will make it easier for Normet to develop online features and applications customized to customer needs — without having to modify the ecommerce engine or the back-end software.

One development already helping to smooth the buying process is a feature that lets either a maintenance contractor or the final customer (or both, depending on how they operate) submit an online request for parts and supplies for a maintenance project on a specific type of Normet equipment. Normet will then return an online list of recommended products with prices more quickly and accurately than would typically be done through phone or email, Jaarinen says.

Normet fulfillment workers preparing to ship orders.

“They can drop that request in place on the ecommerce site, then see the availability and the pricing and also do the purchase,” he says. Normet will consider additional online services through ongoing development projects to introduce more value into the purchasing process, Jaarinen says.

New IoT-backed ordering to come

One project in the works is using the ecommerce platform’s composable architecture and internet-of-things sensors to develop a system for pulling real-time information on the equipment’s operation and need for parts and service. The composable architecture with its APIs and microservices enables Normet to connect to the commerce platform’s commercially available or in-house-developed software modules that, for example, could show customers on Normet’s ecommerce site their equipment’s operating status and any recommended replacement parts, supplies and services.

“We are able to get real-time data from all records, which means we can analyze the wear and tear of the equipment and predict upcoming maintenance,” Jaarinen says. “And once we link this data to the ecommerce store, the customer can see what they need to order. And they can order the parts beforehand to have them on site when they need them.”

“This is not integrated today,” Jaarinen says, “but in the next year, most likely, yes.”

“We aim to be selling more than parts,” he adds. “We want to provide more services as well from the online store.”

Sign up

Sign up for a complimentary subscription to Digital Commerce 360 B2B News, published 4x/week. It covers technology and business trends in the growing B2B ecommerce industry. Contact editor Paul Demery at [email protected] and follow him on Twitter @pdemery.

Follow us on LinkedIn and be the first to know when we publish Digital Commerce 360 B2B News content.

Favorite